Working together for greater sustainability and competitiveness through intelligent and sovereign data use along the value chain

Karlsruhe/Vienna – July 18, 2022. champI4.0ns, a recently launched project, brings together data-driven innovations with practical use cases along the value chain emanating from wood as a raw material. Partners from Austria and Germany pool their expertise to actively advance the manufacturing industry. Martin Benfer, research associate at the Karlsruhe Institute of Technology and responsible for the consortium management on the German side, emphasizes: “The term Industry 4.0 has been shaping the discussion about increasing digitization and networking in industrial and service-related value chains for around ten years – this discussion must now turn into practice. By working closely with representatives of the value chain, champI4.0ns aims to make a significant contribution here.

Sustainability through intelligent use of data

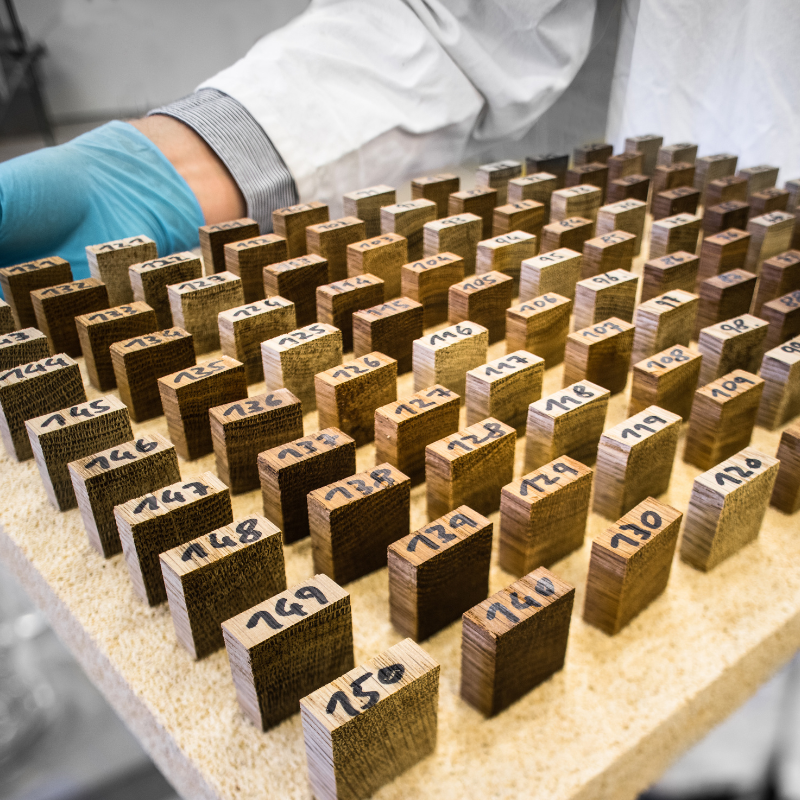

The wood industry is an important economic sector in both Austria and Germany. Wood is a sustainable and future-oriented material, but at the same time the processing of the raw material is very machine and energy intensive. Therefore, especially against the background of the Twin Transition – which is characterized by a digital and an ecological transformation – it is important that companies in the wood industry work on increasing efficiency and conserving resources. The variability of the renewable raw material is a challenge in numerous production processes that can be overcome with the help of data. Even though there is much to be said for the intensive use and exchange of data along the value chain, companies in the wood industry differ greatly in terms of their degree of digitization. There are pioneers as well as laggards, and small and medium-sized companies in particular run the risk of falling behind in the competition. This is precisely where champI4.0ns wants to make a contribution and define cross-industry best practices for intelligent and sovereign data use based on the wood industry.

Wood industry as a role model for data use in production

Achieving sustainability goals as well as strengthening competitiveness should succeed through the use of data in areas such as tracking materials and products, improving utilization of machinery and equipment, ensuring quality standards, or reducing scrap and transportation. “champI4.0ns will advance the use of production-relevant data by using examples from the wood industry to show how intelligent and sovereign use of data can succeed in an ecosystem of very diverse players,” explains Daniel Bachlechner, group leader at Fraunhofer Austria and entrusted with consortium leadership on the Austrian side. For this purpose, flexibly applicable methods and services for addressing central challenges are developed and provided. The focus here is equally on using the data as comprehensively as possible and on safeguarding the interests of the stakeholders involved. The added value that these methods and services can create is demonstrated using concrete use cases.

champI4.0ns stands for an open culture of innovation

Demonstrators that can be embedded in existing data infrastructures and ecosystems will receive special attention in champI4.0ns. Here, the potential that can be realized through innovative methods and services for intelligent and sovereign data use in combination with coordinated guidelines and standards is shown. At its core, it is about creating an open and agile culture of innovation that makes sustainable development in production possible. The champI4.0ns consortium places particular emphasis on taking into account preliminary work from activities such as Data Market Austria in Austria and ReKoNet in Germany, making full use of interfaces to current initiatives such as International Data Spaces Association (IDSA), Gaia-X Association, and the Big Data Value Association (BDVA), and playing a central role in shaping future data service ecosystems such as the Green Data Hub.

Project background

The bilateral lead project is jointly funded by the Austrian Federal Ministry for Climate Protection, Environment, Energy, Mobility, Innovation and Technology (BMK) and the German Federal Ministry of Economics and Climate Protection (BMWK) (FFG grant number 883417). Over a period of four years and with a total volume of EUR 8,613,396 (or a funding amount of EUR 5,467,935), the consortium consisting of 18 partners is working on sustainable innovation at the interface between the timber industry and data science. On the Austrian side, the partners are Fraunhofer Austria, Kompetenzzentrum Holz, Joanneum Research, Danube University Krems, Data Intelligence Offensive, Business Upper Austria, Semantic Web Company, nexyo, IoT40, NET-Automation, ADH Mölltal Möbel, Weitzer Woodsolutions and Hasslacher, and on the German side Karlsruher Institute of Technology, RWTH Aachen, Pfleiderer, Siempelkamp and Siemens. The project aims to make tangible the added value that the intelligent and sovereign use of data can bring to production – in the wood industry and beyond.

Queries:

Nina Popanton

champI4.0ns project communication

nina.popanton@dataintelligence.at

+43 664 20 45 965