champI4.0ns use cases

In champI4.0ns, four use cases are being worked on, all of which – with different weighting – deal with traceability, planning & control and quality assurance.

Application partner:inside: ADH Mölltal Furniture & I0T40

Application partner:inside: ADH Mölltal Furniture & I0T40

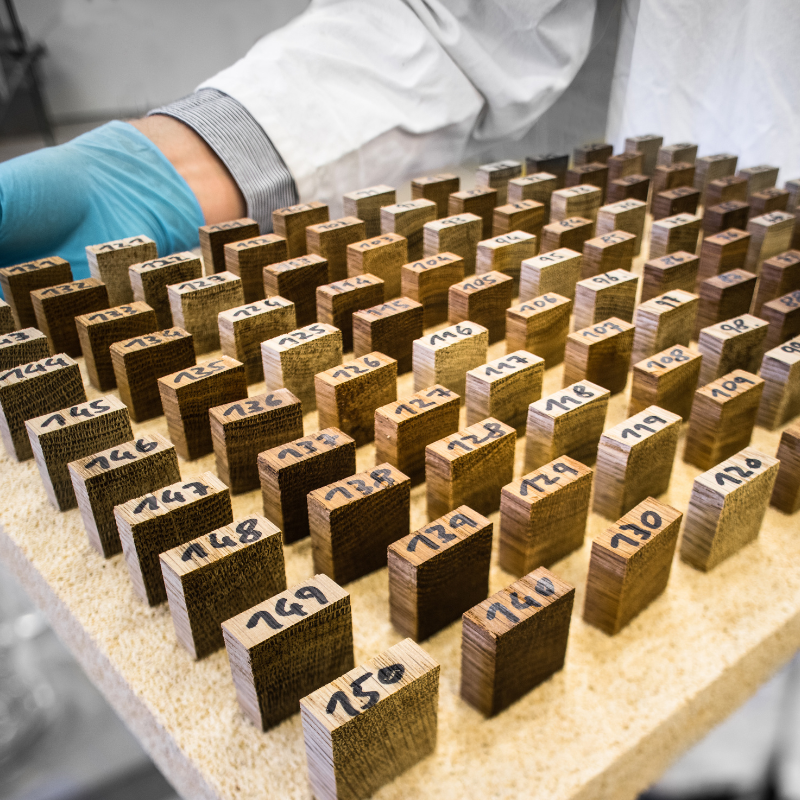

Focus: Traceability

Initial situation: Buyers of furniture cannot be sure that the wood used comes from sustainable forestry

Objective: Counterfeit-proof material tracking from tree to piece of furniture

Solution approach.

- Logs can be reliably identified via annual rings and other features

- Data along the entire process from the forest to the sawmill to the manufacture of the end product is clearly assigned and stored in a central database

- A digital material or product passport for wood and furniture is created

Application partner:inside: HASSLACHER PREDING Holzindustrie GmbH & NET-Automation GmbH

Application partner:inside: HASSLACHER PREDING Holzindustrie GmbH & NET-Automation GmbH

Focus: Planning and control

Initial situation: Since pellet production is influenced by numerous factors, no standardized control strategies exist

Objective: Autonomous process control in pellet production

Solution approach:

- Certain product quality is achieved with minimum use of resources and maximum utilization of production facilities

- Data for the training of AI-based control is generated using simulations, among other things

- Models are to be built in a decentralized manner, compared with each other and transferred between similar plants

Application partners:inside: Weitzer Woodsolutions & Joanneum Research

Application partners:inside: Weitzer Woodsolutions & Joanneum Research

Focus: Quality assurance

Initial situation: The production of stairs is usually based on rough dimensional specifications, and adjustment to the natural dimensions only takes place on site. A proof of concept for recording the natural dimensions already before production is available, but an economic application is not yet possible, mainly due to the high resource requirements.

Objective: Networked data chains in staircase production

Solution approach.

- AI-based collection of natural measurements on site with a handheld device

- Efficient (broadband) data communication from the construction site to data evaluation and production

- Methods for autonomous data processing are used in product planning

Application partner:inside: Pfleiderer & Siempelkamp

Application partner:inside: Pfleiderer & Siempelkamp

Focus: Planning and control, quality assurance, traceability

Initial situation: A variable natural raw material and the complexity of manufacturing make it difficult to set manufacturing processes. Data is collected at various points, but cannot be adequately used to guide the process.

Objective: Optimized model-based process control and quality prediction

Solution approach.

- Collection of additional data in production and from suppliers and integrated use of this data or transfer to customers

- Dashboards help plant operators make process control decisions

- Materials and products are tracked throughout the value chain and a carbon footprint is assigned to products

- Material properties that cannot be measured non-destructively are determined on the basis of measurable properties